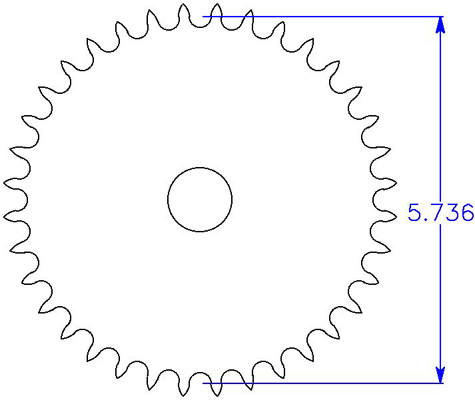

Link Chain Sprocket Design

22 15 with welded teeth or in some cases cast with a solid pocket tooth form.

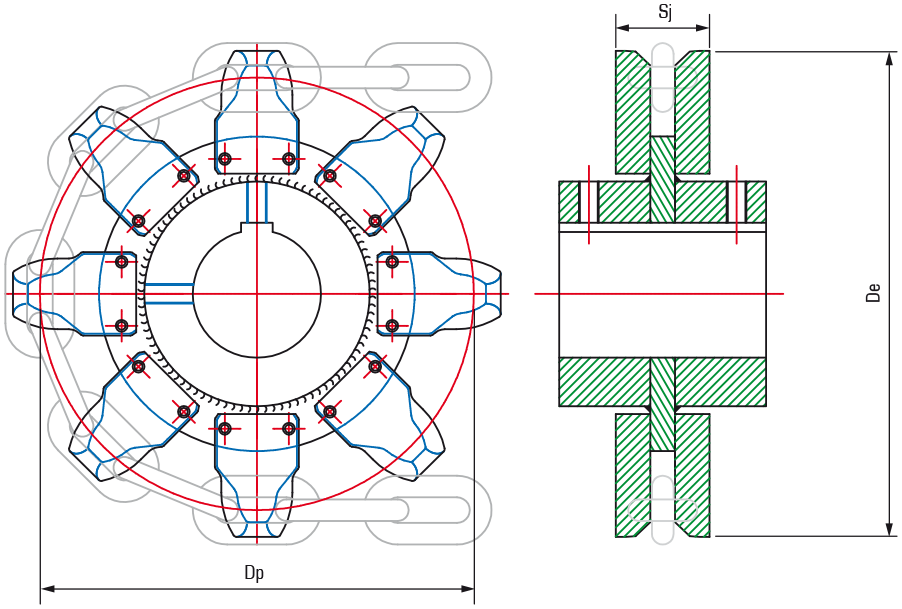

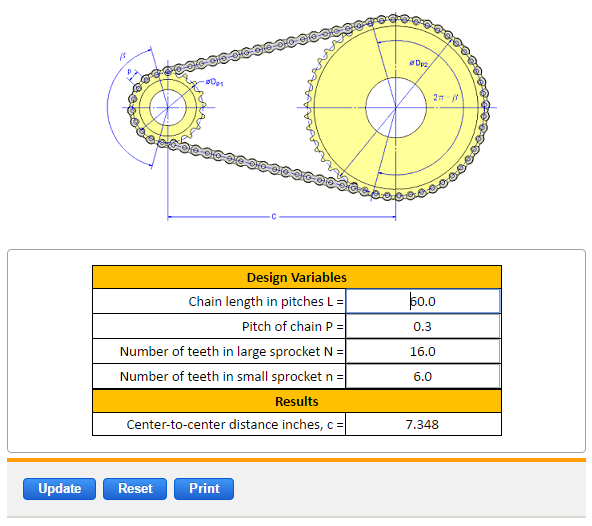

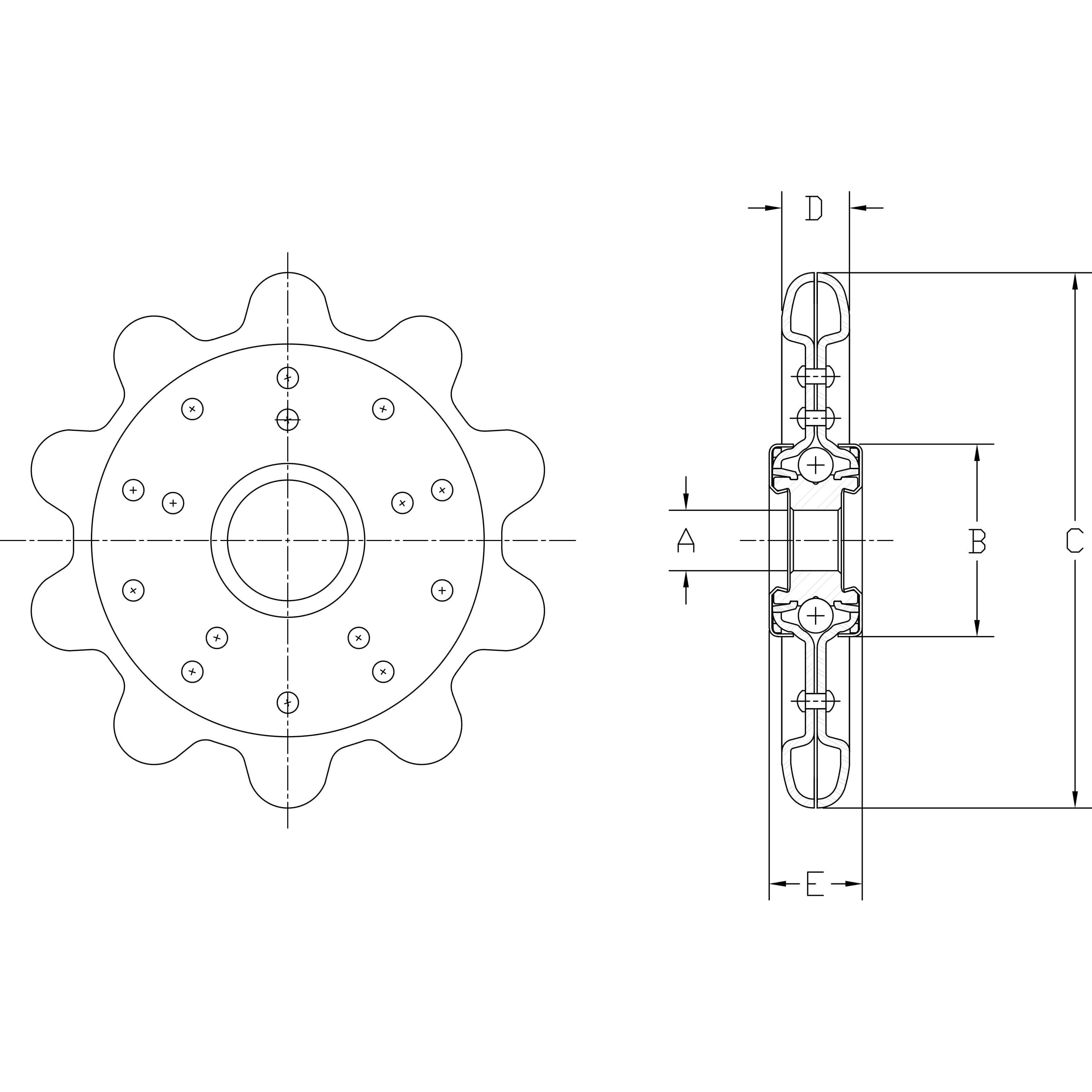

Link chain sprocket design. Teeth dp de sj inches 1450 6t 6 7 637 9 137. A g2 attachment outer plate. B g2 attachment welded or rivetted to link plate. Sprocket tooth design formulas refer to fig.

8 3 roller and bush chains. G attachments are normally fitted only to one side of the chain. The shape of the tooth form. 2 design of steel roller chains.

Sprockets consist of a disk with straight teeth projecting radially. 1 sprocket tooth geometry the tooth form of a sprocket is derived from the geometric path described by the chain roller as it moves through the pitch line and pitch circle for a given sprocket and chain pitch. Sprockets will only work correctly with chain and other sprockets if they are on parallel shafts and the teeth are in the same plane. Table 22 26 jk code no.

The snap together feature also makes the chain adjustable to any loop length without the need for special splicing tools. The high standard of quality assurance conforms with the high requirements of the automotive industry of iso 9002 1987 and other national and interna. Plate then the shroud of the chain sprocket has to be removed to clear the plate. Serv o link chain and sprockets provide the designer with a unique and highly versatile means of transmitting rotary power.

Serv o link s unit link chain design eliminates the need for a master link.